Product Description:

When it comes to thermal spray powders, our product offers a high-quality solution for various coating applications. The powder is designed to be used in flame, plasma, and HVOF spray processes, making it versatile and suitable for different industrial needs.

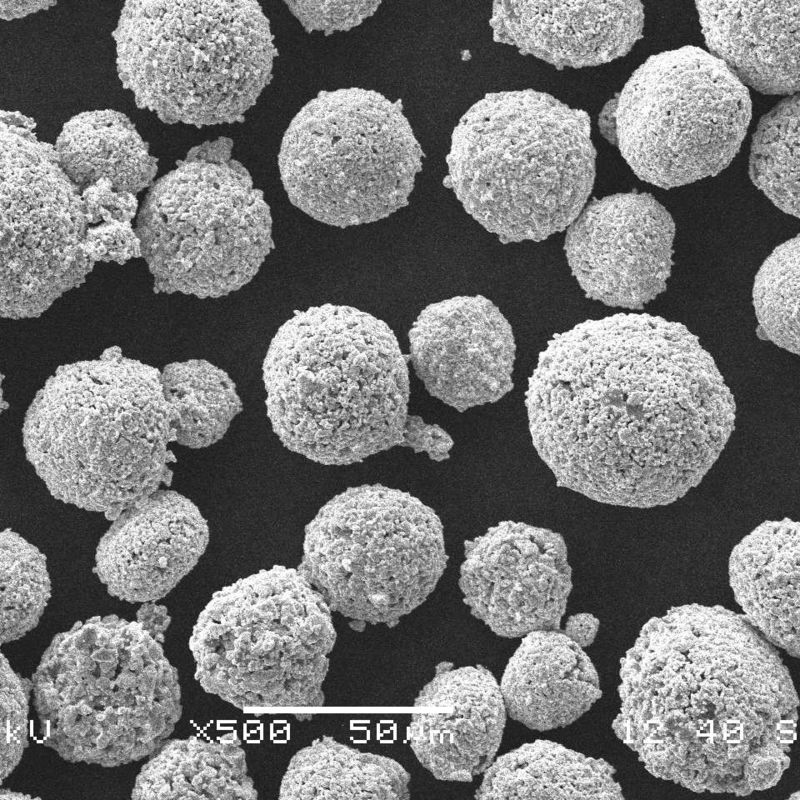

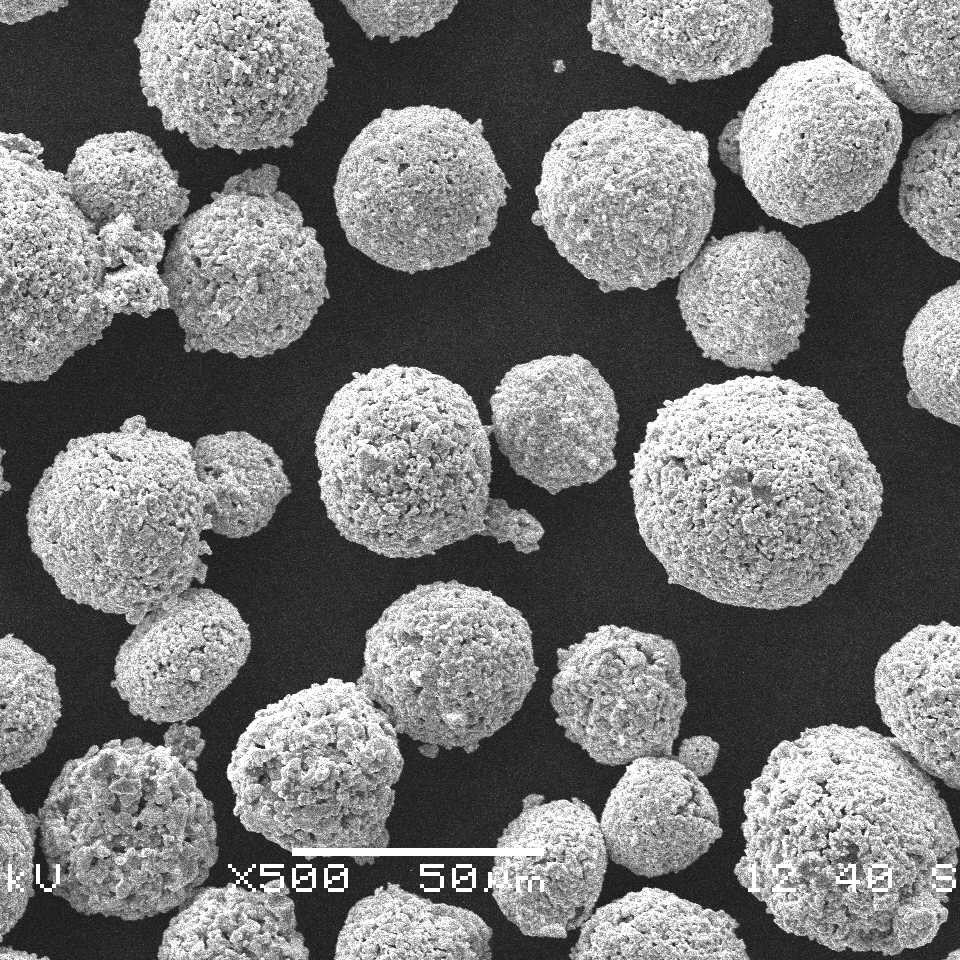

The key component of this thermal spray powder is the WC-CO-CR material, known for its exceptional hardness and wear resistance properties. The medium particle size of WC ensures good flowability during the spraying process, resulting in consistent and uniform coatings.

The irregular shape of the powder particles contributes to better adhesion and bonding with the substrate, ensuring a strong and durable coating. Additionally, the angular and blocky morphology of the particles further enhances the coating's toughness and resistance to mechanical stress.

One of the important characteristics of this thermal spray powder is its controlled porosity, ranging from 1% to 5%. This porosity level is optimized to promote adhesion and reduce the risk of delamination, ensuring the longevity and performance of the coating.

Whether you are looking to enhance the wear resistance of components or protect them from corrosion, our HVAF WC-CO-CR thermal spray powder is an excellent choice. The coating materials WC-CO-CR offer superior performance in harsh operating environments, making them ideal for a wide range of applications.

Overall, our thermal spray powder is a reliable and effective solution for your coating needs, providing excellent wear resistance, corrosion protection, and durability. With its unique combination of attributes, including spray process compatibility, particle size, shape, morphology, and porosity control, this product delivers exceptional results in various industrial applications.

Features:

-

Product Name: Thermal Spray Powders

-

Color: Dark-gray Powder

-

Size Of WC: Medium Particle Of WC

-

Apparent Density: 2.9 – 5.8 G/cm3

-

Shape: Irregular

-

Spray Process: Flame, Plasma, HVOF

-

Coating Materials: WC-10Co-4Cr, WC-CO-CR, WC-CO-CR

Technical Parameters:

|

Chemical Composition

|

Metallic Or Ceramic

|

|

Morphology

|

Angular / Blocky

|

|

Apparent Density

|

2.9 – 5.8 G/cm3

|

|

Corrosive Wear Resistance

|

Corrosive Wear Resistance

|

|

Typical Hardness

|

1400-1700 HV0.1

|

|

Porosity

|

1-5%

|

|

Chemicals

|

Ni 17.5-22% C 7.5-10% Cr Balanced

|

|

Spray Process

|

Flame, Plasma, HVOF

|

|

Shape

|

Irregular

|

|

Hardness

|

500-2000 HV

|

Applications:

One of the key application areas for the Thermal Spray Powder WC-10Co-4Cr is in industries where components are subjected to corrosive wear, such as in the oil and gas, aerospace, and automotive sectors. The powder's chemistry of WC 12Ni and its metallic or ceramic composition make it well-suited for providing a protective coating that enhances the durability and longevity of parts.

With a hardness range of 500-2000 HV, this HVOF WC-10Co-4Cr powder is also effective in improving the wear resistance of components exposed to abrasive environments. The irregular shape of the powder particles allows for a uniform and dense coating, ensuring optimal performance.

The BODA Fine Size WC-10Co-4Cr powder is certified with ISO9001:2015, guaranteeing its quality and reliability. Customers can order a minimum quantity of 50kgs at a competitive price range of $60-65/kgs, with packaging details of 50kgs per drum. The delivery time is quick, ranging from 7-10 days, and payment terms are open for negotiation.

With a supply ability of 10 tons per month, this thermal spray powder is readily available for various industrial applications. Whether it's for repairing or enhancing components, the BODA WC-10Co-4Cr powder offers a cost-effective solution for achieving superior performance and extending the service life of parts.

Ваше сообщение должно содержать от 20 до 3000 символов!

Ваше сообщение должно содержать от 20 до 3000 символов! Пожалуйста, проверьте свою электронную почту!

Пожалуйста, проверьте свою электронную почту!  Ваше сообщение должно содержать от 20 до 3000 символов!

Ваше сообщение должно содержать от 20 до 3000 символов! Пожалуйста, проверьте свою электронную почту!

Пожалуйста, проверьте свою электронную почту!